Present

The Holtex team specialise in a wide variety of products from short lead times to high complexity machined components. In a world that demands results immediately, our fine crew of apprentice trained engineers will do their utmost to work to your requirements.

Industries we currently support include; automotive, oil and gas, medical, powertrain, aerospace, food and drink and agriculture. We are ISO9001 accredited and are more than willing to discuss opportunities or additional requirements.

For further information or to tell us about your own project please get in touch.

- • Engineering design.

- • Generative design.

- • Process optimisation.

- • Metrology.

- • Machine capacity.

- • Machine refurbishment.

- • Reverse engineering.

BRINGING YOUR IDEAS TO LIFE...

ENGINEERING DESIGN

With in-house experts in both advanced machining strategies and machine tooling, we offer consultation on improving your existing supply chain or in-house machining.

Improving productivity and profit margin without compromising on quality.

Using high speed machining strategies, technology in carbide tooling, work holding and pre-setting, the Holtex team are able to maximise speeds and feeds to reduce component cycle times.

Whether this be on your components that we manufacture in house or for deployment within your supplier base.

- • Cycle time reduction

- • Tool wear optimisation

- • Tool choice & consumption rate

- • Automation

GENERATIVE DESIGN

Have an idea but not sure how to make it reality? We offer a consultation process to progress your idea from initial concept, through prototype manufacture and validation to full production.

We can assist with component / test design, fixture manufacture and result analysis to evolve your product to meet your technical requirements.

We have assisted several clients in a range of areas from full concept realisation, product redesign, full validation to development of novel and unique ideas with patents granted.

Projects no matter how big or small are handled in a sensitive nature with full non-disclosure agreed and signed before work commences.

See our blog for real world examples of improvements achieved.

PROCESS OPTIMISATION

With in-house experts in both advanced machining strategies and machine tooling, we offer consultation on improving your

existing supply chain or in-house machining.

Improving productivity and profit margin without compromising on quality.

Using high speed machining strategies, technology in carbide tooling, work holding and pre-setting, the Holtex team are able to maximise speeds and feeds to reduce component cycle times.

Whether this be on your components that we manufacture in house or for deployment within your supplier base.

- • Cycle time reduction

- • Tool wear optimisation

- • Tool choice & consumption rate

- • Automation

METROLOGY

Within our inspection department we have a wide range of manual and digital measurement equipment including CMM, manual and optical scanning technology.

For more complex components or where full surface geometry verification is required, we have the latest technology in 3D scanning to replicate your component in 3 dimensions which can then be compared directly to a nominal model.

3D scanning can be completed at our site or yours, with results available in real time and reports available the next working day.

Holtex also have access to CT scanners for non-destructive subsurface inspection to identify material defects in new or failed components.

3D PRINTING

A revolutionary manufacturing method, 3D printing gives the ability for design staff to work “outside the box” and opens

the possibility for geometry that would otherwise be possible through standard machining.

This, coupled with the ability for the printers to manufacture parts overnight of varying complexity, has given 3D printing a firm home at Holtex.

- • Standard Resin

- • Durable Resin

- • Elastic

- • Flexible

- • High Temperature

- • Rigid

- • Tough

- • Castable Wax

Check Out Our

Kit List!

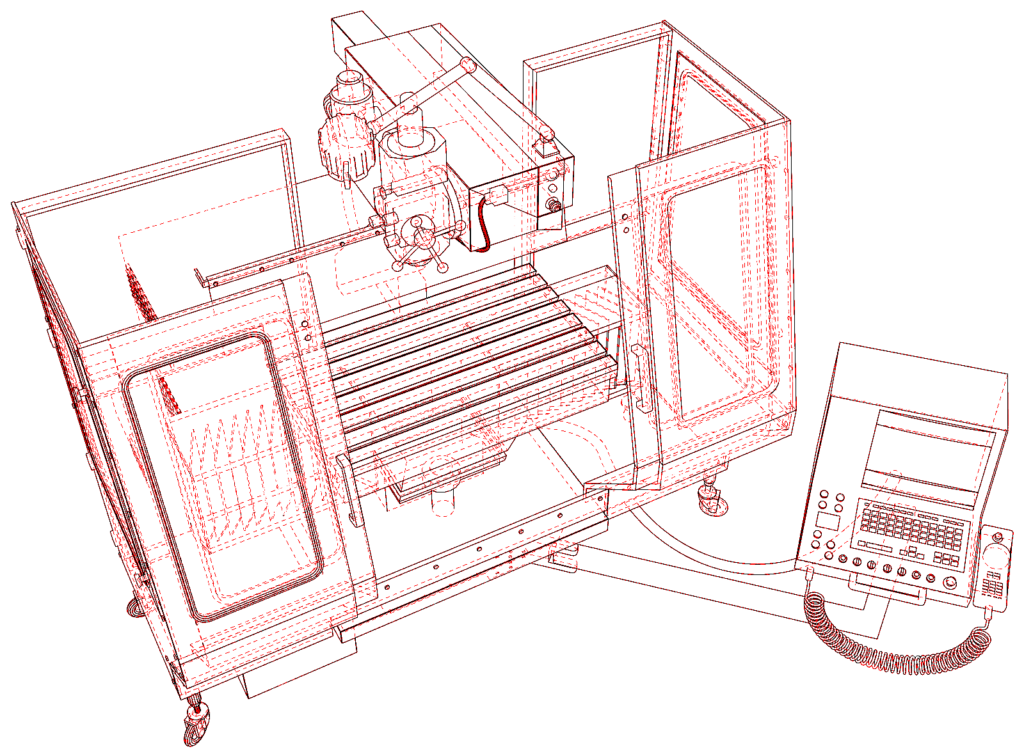

REVERSE ENGINEERING

In addition to new concepts and ideas, the Holtex team are able to turn your samples or hardware into full CAD geometry. Using cutting edge optical scanning technology, combined with CMM measurements, 3D and 2D models and drawings can be produced down to accuracy of +-3 μm.

Models generated can be used for iterative design, laying down new or improved mould tooling, understanding competition designs and dimensional verification.

- • Modification of design to meet new requirements

- • Design optimisation for manufacture

- • Dimensional analysis of scanned component to nominal 3D model

- • Generate bespoke machining profiles to rework of out of spec components to match an existing 3D model or known good component

- • 3D Optical Scanner (0.05-0.1mm accuracy)

- • Aberlink Xtreme CMM (+- 3 μm)

- • Extensive Measurement Facility