FUTURE

The world has changed in recent months, with reshoring exercises and economic uncertainty in many businesses’ future. As a nation, the UK and its manufacturing scene needs to diversify in upcoming and green technology, building resilience and growth for the future.

Holtex’ is currently working on ongoing projects with an aim focused on the following;

Our own carbon neutral manufacturing plant.

Algae photobioreactors & algal fertiliser.

Zero emissions transport supported by our own electropolishing.

CO2 Fixation system.

Micro hydrogen fuel cell.

For further information or to tell us about your own project please get in touch.

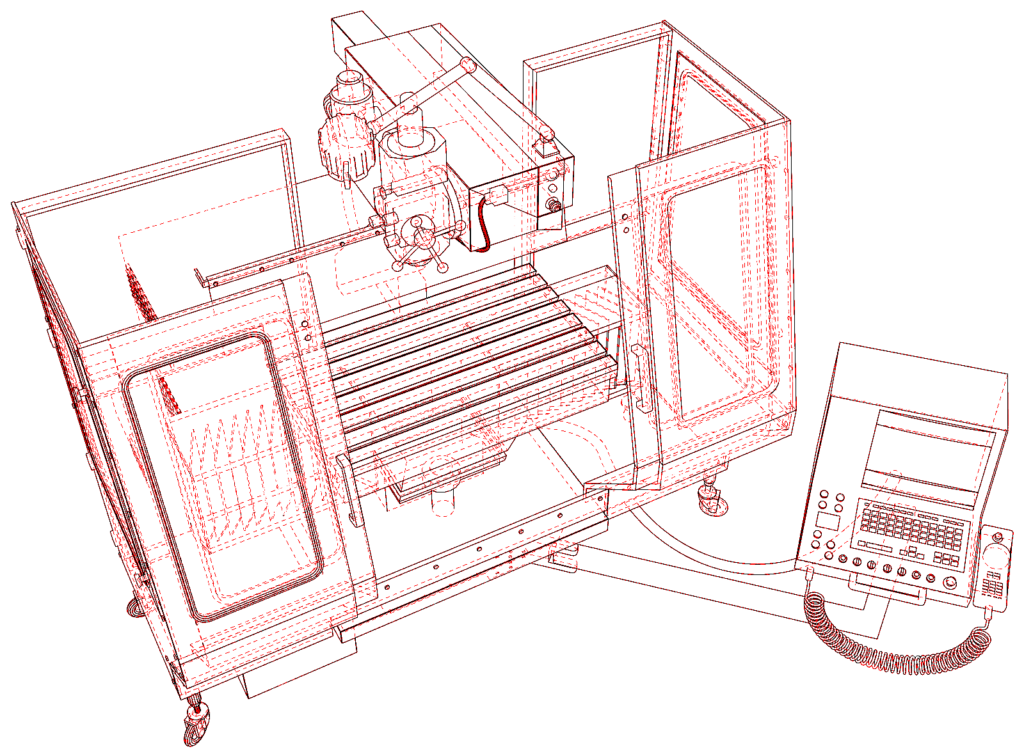

- • CNC machining.

- • Milling & turning.

- • Wire EDM cutting.

- • Process optimisation.

- • Metrology.

- • Reverse engineering.

- • 3D printing.

GREEN TECHNOLOGY

As a company committed to improving the environment, we have several active projects currently ongoing including electric vehicle development, reductions in vehicle emissions and alternative methods in remove CO2 from the atmosphere to assist companies in becoming carbon neutral.

Get in touch to understand more how we can help your business.

FIND OUT HOW HOLTEX CAN HELP YOU TURN YOUR PARTS GREEN.

- • Reduce your carbon footprint.

- • Improve productivity.

- • Transition to sustainable materials.

- • Reduce cost throughout your supply chain.

ENGINEERING DESIGN

With in-house experts in both advanced machining strategies and machine tooling, we offer consultation on improving your existing supply chain or in-house machining.

Improving productivity and profit margin without compromising on quality.

Using high speed machining strategies, technology in carbide tooling, work holding and pre-setting, the Holtex team are able to maximise speeds and feeds to reduce component cycle times.

Whether this be on your components that we manufacture in house or for deployment within your supplier base.

- • Cycle time reduction

- • Tool wear optimisation

- • Tool choice & consumption rate

- • Automation

RESHORING...

WANT TO MOVE YOUR PARTS BACK FROM OVERSEAS BUT CAN’T AFFORD THE INCREASE?

- • We can help you use tools to modify your designs to suit UK based manufacturing.

- • Reduce cost to manufacture within the UK.

- • Shorten your lead times.

- • Improve flexibility and support local economies.

- • Design for manufacture and assembly optimisation.

Check Out Our

Kit List!

GENERATIVE DESIGN

Have an idea but not sure how to make it reality? We offer a consultation process to progress your idea from initial concept, through prototype manufacture and validation to full production.

We can assist with component / test design, fixture manufacture and result analysis to evolve your product to meet your technical requirements.

We have assisted several clients in a range of areas from full concept realisation, product redesign, full validation to development of novel and unique ideas with patents granted.

Projects no matter how big or small are handled in a sensitive nature with full non-disclosure agreed and signed before work commences.

3D PRINTING

A revolutionary manufacturing method, 3D printing gives the ability for design staff to work “outside the box” and opens

the possibility for geometry that would otherwise be possible through standard machining.

This, coupled with the ability for the printers to manufacture parts overnight of varying complexity, has given 3D printing a firm home at Holtex.

-

• Polymers

- • Metal

METROLOGY

Within our inspection department we have a wide range of manual and digital measurement equipment including CMM, manual and optical scanning technology.

For more complex components or where full surface geometry verification is required, we have the latest technology in 3D scanning to replicate your component in 3 dimensions which can then be compared directly to a nominal model.

3D scanning can be completed at our site or yours, with results available in real time and reports available the next working day.

Holtex also have access to CT scanners for non-destructive subsurface inspection to identify material defects in new or failed components.