Sustainability isn’t just a buzzword at Holtex — it’s a design principle. In response to growing demand for environmentally conscious engineering, we recently collaborated with a West Yorkshire automotive supplier to reduce material waste in their machining process.

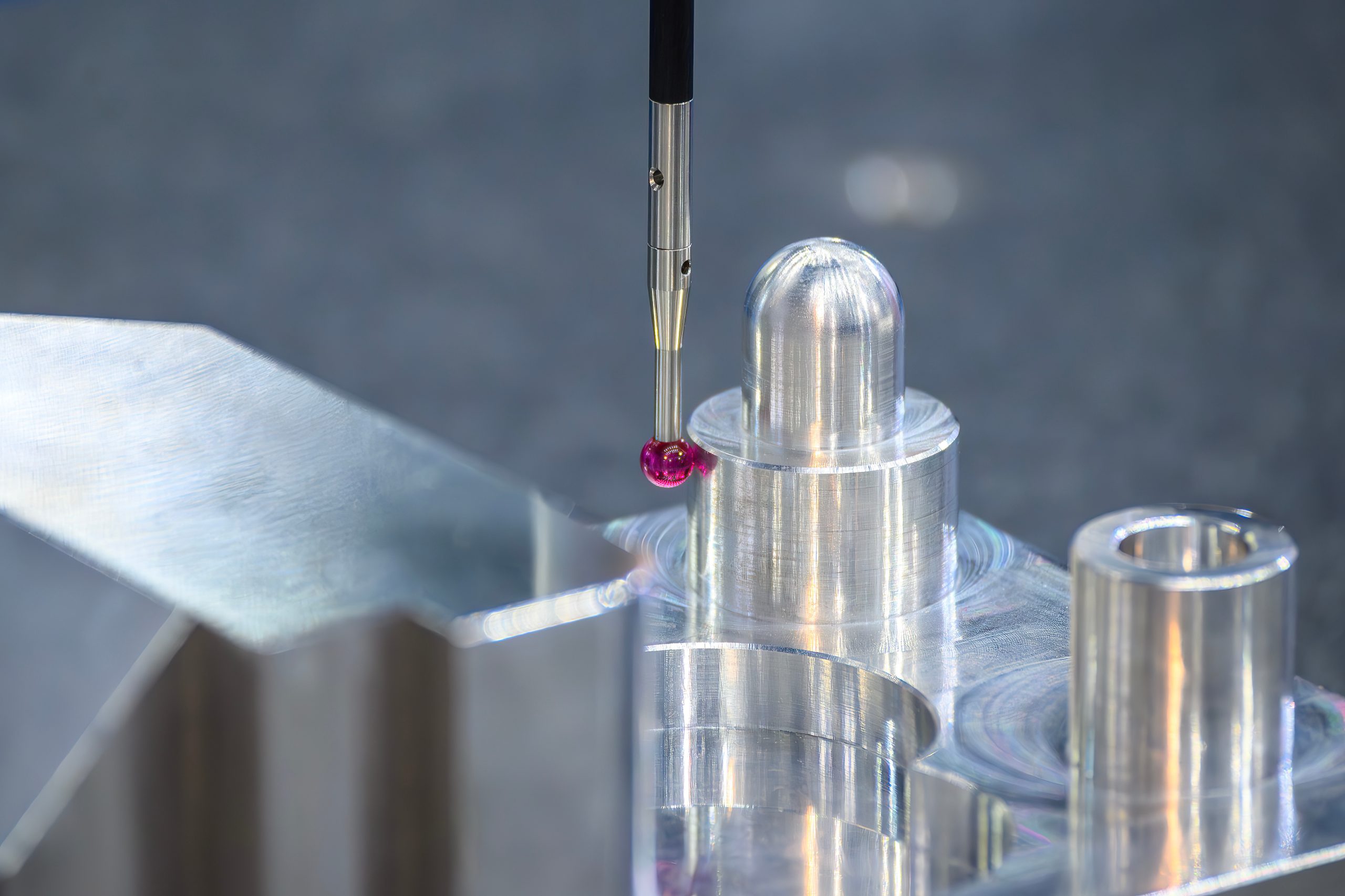

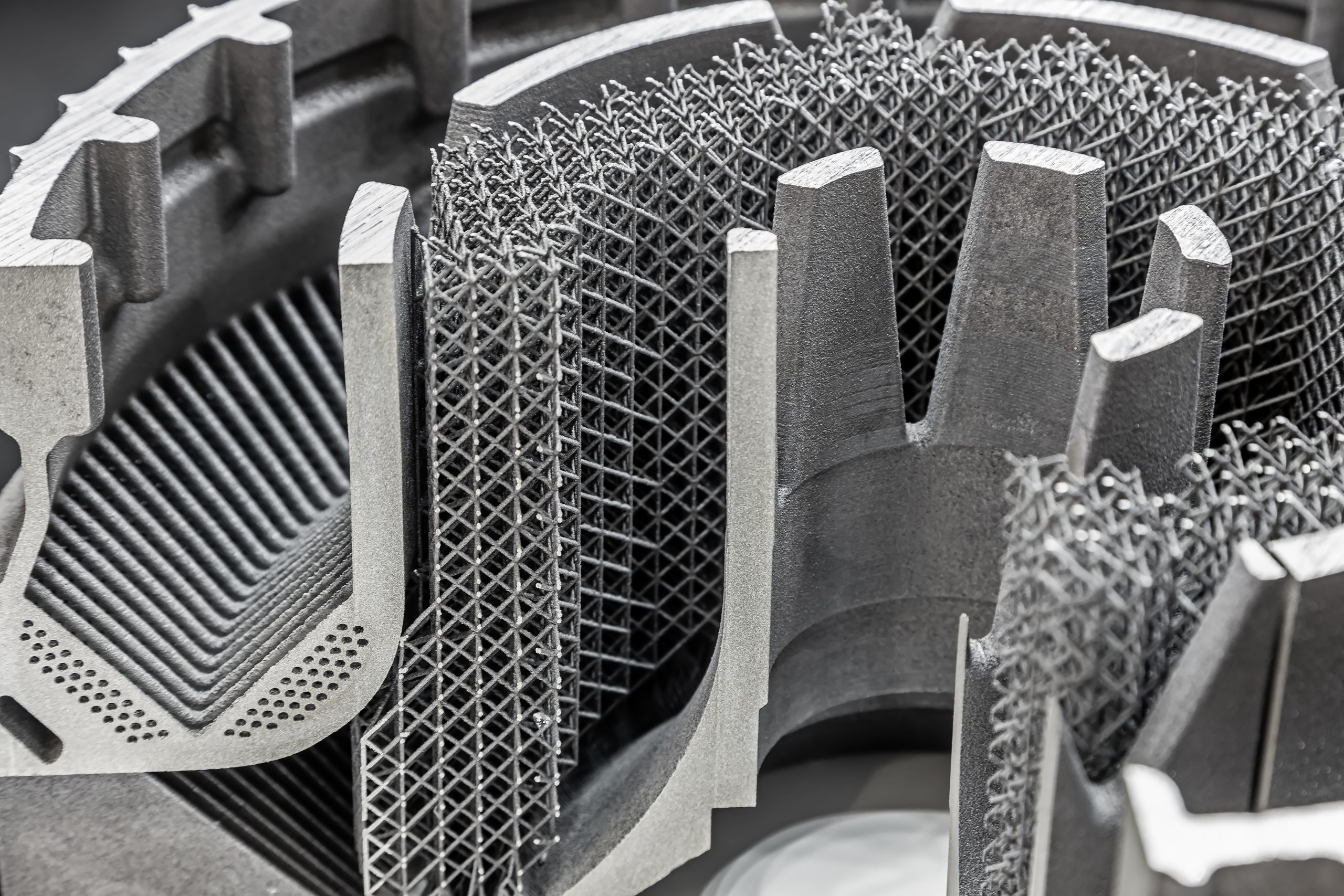

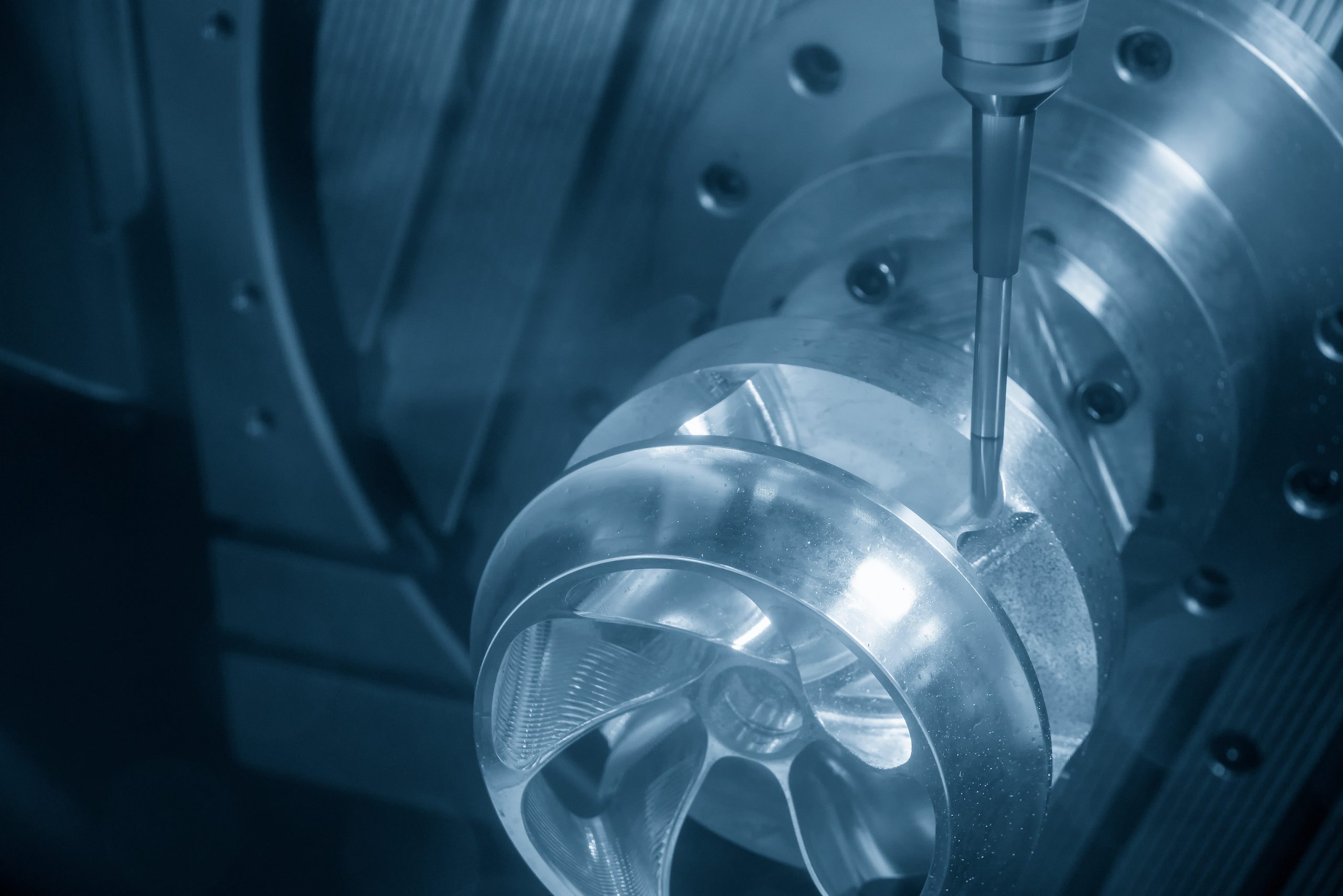

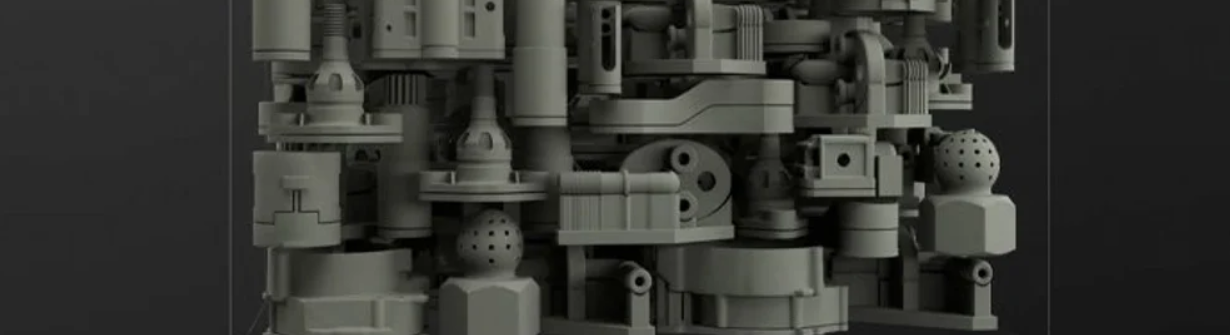

Our client was facing high levels of aluminium swarf during the manufacture of drivetrain components. After an initial process review, Holtex proposed a re-engineered modular tooling system that optimised part nesting, reduced unnecessary stock material, and improved repeatability across batches.

By combining simulation software with on-machine verification, we fine-tuned cutting paths to minimise tool wear and material waste. The result? A 40% reduction in swarf, improved part consistency, and a measurable drop in cycle times. We also provided training to the client’s operators to help embed best practices for sustainable machining.

This project exemplifies how small design decisions can have large environmental impacts. Beyond cost savings, the new tooling system supports the client’s ISO 14001 environmental targets and boosts their green credentials in a competitive supply chain.

At Holtex, we believe that the future of manufacturing lies in intelligent design, responsible sourcing, and long-term thinking. Our role is to help clients improve not only their output, but their impact. Greener. Smarter. Better. That’s how we build the future — one project at a time.

Our client was facing high levels of aluminium swarf during the manufacture of drivetrain components. After an initial process review, Holtex proposed a re-engineered modular tooling system that optimised part nesting, reduced unnecessary stock material, and improved repeatability across batches.

By combining simulation software with on-machine verification, we fine-tuned cutting paths to minimise tool wear and material waste. The result? A 40% reduction in swarf, improved part consistency, and a measurable drop in cycle times. We also provided training to the client’s operators to help embed best practices for sustainable machining.

This project exemplifies how small design decisions can have large environmental impacts. Beyond cost savings, the new tooling system supports the client’s ISO 14001 environmental targets and boosts their green credentials in a competitive supply chain.

At Holtex, we believe that the future of manufacturing lies in intelligent design, responsible sourcing, and long-term thinking. Our role is to help clients improve not only their output, but their impact. Greener. Smarter. Better. That’s how we build the future — one project at a time.