Precision Machining & Manufacturing for Critical Sectors

ISO 9001 accredited CNC machining, batch manufacturing, and rapid prototyping services. Expert precision engineering for aerospace, automotive, defence, and energy sectors.

CNC Precision Machining Excellence

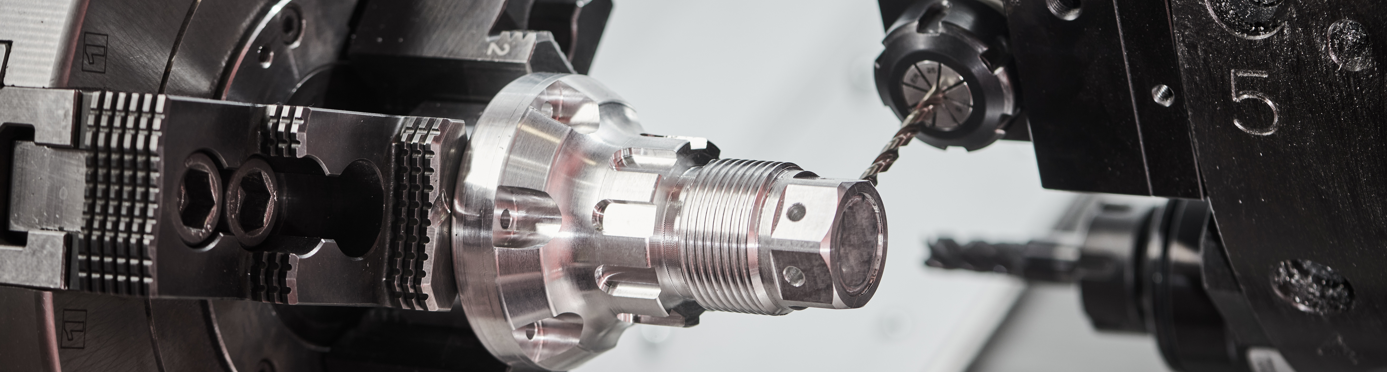

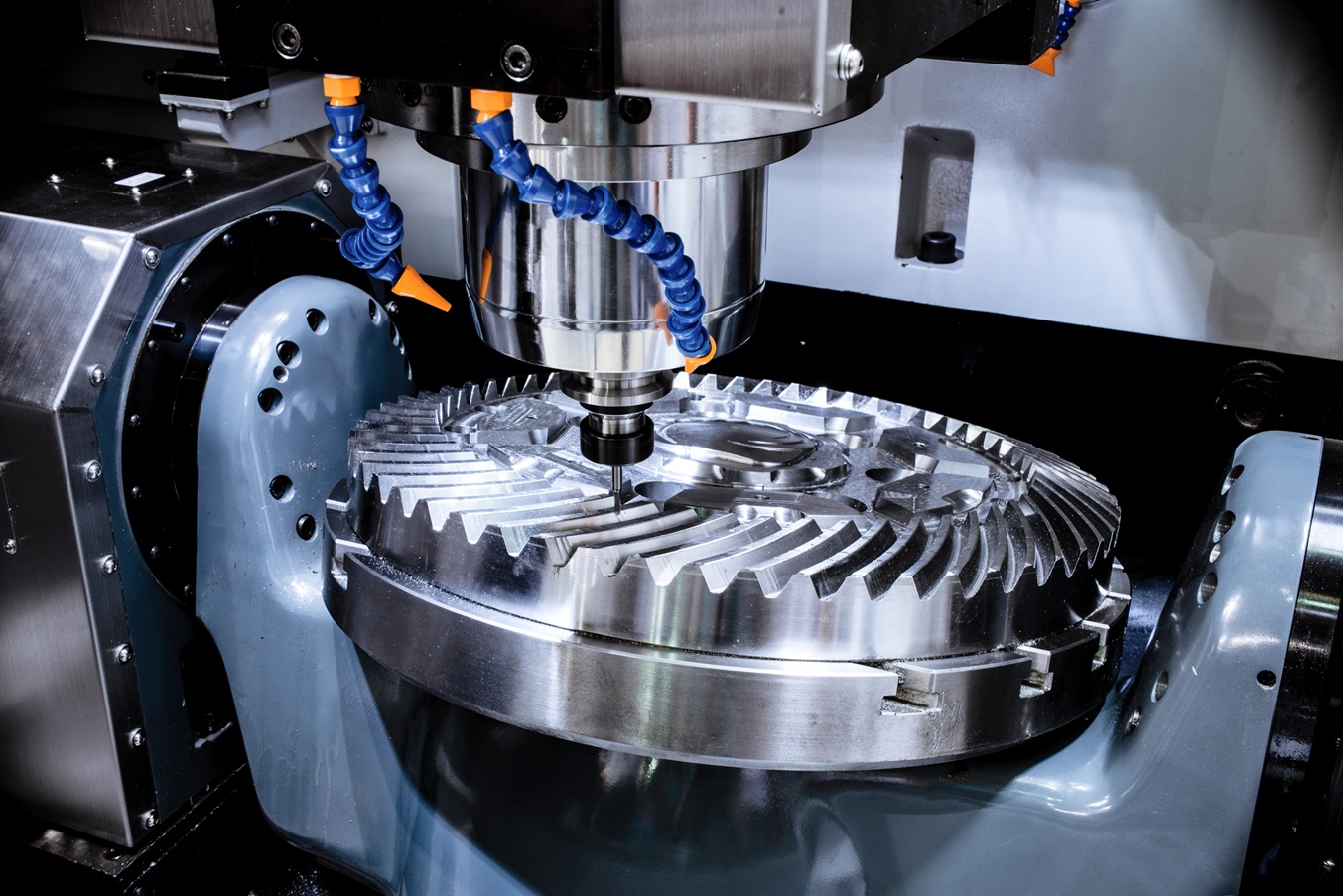

Expert CNC milling, turning, and 5-axis machining for rapid prototyping and batch manufacturing. From complex automotive components to critical aerospace parts, we deliver precision machining with tolerances that meet the most demanding specifications.

CNC Milling & Turning

Multi-axis precision CNC machining

Quality Assurance

Advanced metrology & inspection

Batch Manufacturing

Small to medium production runs

Industries We Serve

Precision machining and rapid prototyping services trusted by aerospace, automotive, defence, rail, oil & gas, and energy sectors across the UK

Automotive

Precision components for automotive manufacturing and powertrain systems

Defence

Mission-critical engineering solutions for defence applications

Aerospace

High-tolerance components for aerospace industry standards

Rail

Reliable engineering for rail transport infrastructure

Oil & Gas

Robust solutions for demanding oil and gas environments

Subsea

Specialized engineering for subsea applications and equipment

Energy

Sustainable solutions for energy sector challenges

Manufacturing

Process optimization and manufacturing excellence

Core Capabilities

Comprehensive engineering services backed by decades of expertise and cutting-edge technology

Engineering Design

Expert design services from concept through to production, leveraging advanced CAD/CAM technologies.

Precision Manufacturing

Complex machined components delivered with exceptional accuracy and short lead times.

Metrology & Reverse Engineering

Advanced measurement and analysis capabilities for quality assurance and component replication.

Machine Refurbishment

Complete machinery refurbishment services supporting sustainability and right-to-repair principles.

Process Optimization

Manufacturing consultancy to improve efficiency, reduce waste, and enhance operational performance.

Advanced Manufacturing Equipment

State-of-the-art machinery enabling precision engineering across all sectors

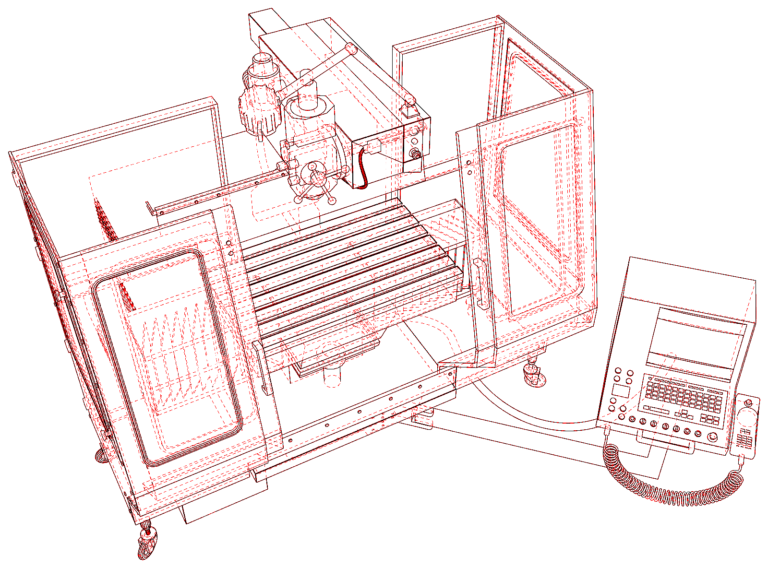

CNC Milling

Hurco VM10i

660x400x500mm | 12000rpm | 20 ATC

Doosan DNM 400ii

12000rpm | 30 tools | 600kg capacity

Doosan DNM 4500

800x450x510mm | 5-axis | Fanuc 0i-M

Hurco VM30i

1200x500x500mm | 20Hp | 12000rpm

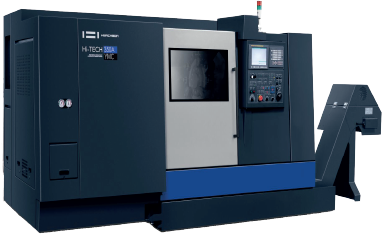

CNC Turning

Hwacheon Cutex 160

Linear guide rails | LNS bar feed

Hwacheon Hi-Tech 300

600mm x 800mm capacity | 2-speed gearbox

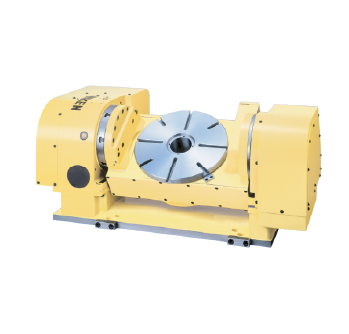

Multi-Axis

Nikken 5-Axis Rotary

Full 5-axis machining capability

Doosan LYNX 2600SY

6-axis mill-turn | 380x610mm | 24 station

Wire EDM

Sodick VN600Q

600x400x310mm travel

Additive Manufacturing

Formlabs Form 2

SLA | 200mm cube

BCN Epsilon W50

FDM | 420x300x400mm | Dual extrusion

GE Concept Laser m2

Metal 3D printing

Finding Solutions to Impossible Problems

Based in Skelmanthorpe, West Yorkshire, Holtex has built a reputation for delivering precision-engineered solutions that others consider impossible. Our highly trained workforce combines traditional craftsmanship with advanced manufacturing technologies.

We operate across three strategic domains: maintaining past machinery, delivering present manufacturing excellence, and developing future sustainable technologies including carbon-neutral manufacturing and green engineering solutions.

ISO 9001 Accredited

Quality management excellence

Expert Workforce

Decades of combined experience

Precision Focus

Uncompromising accuracy

Sustainability

Green technology pioneers

Accreditations & Memberships

"Holtex finds the solution to your impossible problems"

Our commitment to excellence, combined with our investment in both people and technology, ensures we deliver solutions that exceed expectations across automotive, defence, aerospace, rail, energy, subsea, and oil and gas sectors.

Get in Touch

Ready to discuss your engineering challenges? Contact our team to explore how we can deliver precision solutions for your critical applications.

Telephone

01484 684001Location

Unit 1, Skelmanthorpe Technology Park

Station Road, Skelmanthorpe

Huddersfield, West Yorkshire

HD8 9GA, United Kingdom