Kit List

MILLING

3 AXIS CNC

Hurco VM10i

A high speed 3 axis machining centre, with an exceptionally small

footprint but offering and impressive 660x400x500 capacity.

Featuring a 12000rpm, 15Hp, through coolant spindle, mounted on a solid cast frame, it is capable of machining all materials efficiently.

With a 20 station ATC and operated with a Winmax control it has the ability to machine the most complex components efficiently.

Featuring a 12000rpm, 15Hp, through coolant spindle, mounted on a solid cast frame, it is capable of machining all materials efficiently.

With a 20 station ATC and operated with a Winmax control it has the ability to machine the most complex components efficiently.

5 AXIS CNC

Doosan DNM 4500

We have two of these powerful, direct drive, high precision machining

centre with full 5 axis machining capability.

Offering 800x450x510 standard capacity, and 200mm cube 5 axis

capacity with Fanuc 0i-M control.

Supported by Solidworks, Hypermill and Edgecam these machines have an impressive ability to produce the most complex components efficiently in any material.

Supported by Solidworks, Hypermill and Edgecam these machines have an impressive ability to produce the most complex components efficiently in any material.

3 AXIS CNC

Doosan DNM 400ii

Doosan DNM 400 II is primarily used in precision machining applications, including milling, drilling, and tapping of various materials such as metals and plastics. It is suitable for industries such as aerospace, automotive, and general manufacturing.

• High precision and accuracy due to advanced CNC technology. •Versatile machining capabilities with a maximum spindle speed of 12000 RPM, allowing for efficient processing of a wide range of materials. •Ample tool storage with 30 tool pockets, facilitating quick tool changes and reducing downtime. •Robust construction with a weight of 5000 kg, ensuring stability during operation and minimizing vibrations. – Capable of handling heavy parts with a maximum part weight of 600 kg, making it suitable for larger workpieces.

• High precision and accuracy due to advanced CNC technology. •Versatile machining capabilities with a maximum spindle speed of 12000 RPM, allowing for efficient processing of a wide range of materials. •Ample tool storage with 30 tool pockets, facilitating quick tool changes and reducing downtime. •Robust construction with a weight of 5000 kg, ensuring stability during operation and minimizing vibrations. – Capable of handling heavy parts with a maximum part weight of 600 kg, making it suitable for larger workpieces.

5 AXIS CNC

Hurco VM30i

A high speed 3 axis machining centre, offering

1200x500x500 capacity in a very small footprint.

Boasting a 20Hp, 12000rpm, through coolant spindle, mounted on a solid cast frame, it is capable of machining all materials efficiently.

Support by Winmax control it has the ability to run complex, high speed machining strategies allowing the most efficient metal removal.

Boasting a 20Hp, 12000rpm, through coolant spindle, mounted on a solid cast frame, it is capable of machining all materials efficiently.

Support by Winmax control it has the ability to run complex, high speed machining strategies allowing the most efficient metal removal.

TURNING

3 AXIS CNC

Hwacheon Cutex 160

A solid cast frame with linear guide rails

for high precision, ultra high speed 2 axis turning.

Supported by an LNS magazine bar feed its is capable of efficient manufacture of small to medium sized, low to high volume components in any material.

Supported by an LNS magazine bar feed its is capable of efficient manufacture of small to medium sized, low to high volume components in any material.

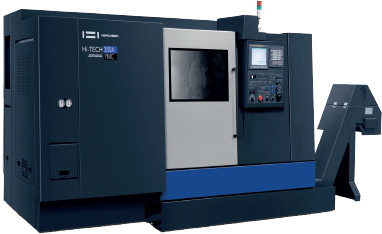

2 AXIS CNC

Hwacheon Hi-Tech 300

A large capacity, high torque, 2 axis CNC lathe with

a 600mm dia. x 800mm capacity and a 2 speed gearbox

drive.

Complimented by a high precision, solid slant bed construction it offer high productivity capabilities for larger components in all materials.

Complimented by a high precision, solid slant bed construction it offer high productivity capabilities for larger components in all materials.

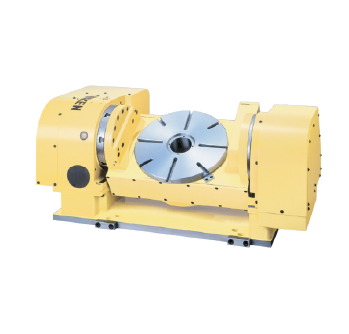

MULTI AXIS MACHINES

5 AXIS MILLING

Nikken 5 axis rotary table

NIKKEN 5th Axis CNC Rotary Tables are renowned for offering unmatched high precision, high rigidity and durability for multiple-axis machining.

6 AXIS MILL TURN

Doosan LYNX 2600SY

The latest addition to our portfolio, is a 380dia x 610mm

capacity dual spindle, 6 axis lathe with high torque driven

tools.

Built on high precision box linear guides in X, Z and Y axis, the 24 station turret provides the accuracy and rigidity to manufacture the most complex components efficiently.

Built on high precision box linear guides in X, Z and Y axis, the 24 station turret provides the accuracy and rigidity to manufacture the most complex components efficiently.

WIRE EDM

Sodick VN600Q

The VN600Q is an advanced line of wire EDMs that features improved finishing circuitry and an upgraded Automatic Wire Threader (AWT).

Specs:

X-Travel: 600 mm

Y-Travel: 400 mm

Z-Travel: 310 mm

X-Travel: 600 mm

Y-Travel: 400 mm

Z-Travel: 310 mm

ADDITIVE

MANUFACTURING

3D PRINTER SLA

Formlabs Form 2

Professional resin 3D printing with exceptional quality,

repeatability and reliability, with a 200mm cube capacity

for manufacturing simple to very complex parts.

It has the capability of producing perfectly functioning components as well as being the absolute solution for rapid prototyping and concept design manufacturing.

It has the capability of producing perfectly functioning components as well as being the absolute solution for rapid prototyping and concept design manufacturing.

3D PRINTER FDM

BCN Epsilon W50

BCN3D Epsilon W50 3D printer provides an efficient

and reliable 3D printing experience with BCN3D’s

high-precision, independent dual extrusion system.

Pair either the Epsilon W50 or Epsilon W27 with

the BCN3D Smart Cabinet to enhance your 3D

printing and production workflow.

Top BCN3D Epsilon W50 3D Printer Features: • Dual Extrusion with IDEX – Print with Multiple Materials at Once • Special Mirror and Duplication Mode Printing • Large format, fully enclosed heated Build Chamber • W50 Build Volume: 420mm x 300mm x 400mm

Top BCN3D Epsilon W50 3D Printer Features: • Dual Extrusion with IDEX – Print with Multiple Materials at Once • Special Mirror and Duplication Mode Printing • Large format, fully enclosed heated Build Chamber • W50 Build Volume: 420mm x 300mm x 400mm

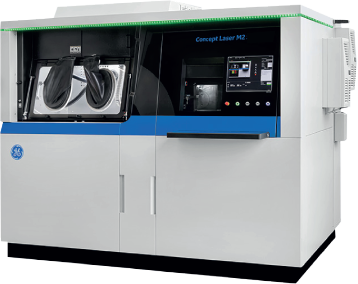

GE Additive

Concept Laser m2

With its superior part quality, usability, and repeatability, the M2 Series 5 is perfect for users at every level, whether they are entry-level users or creating parts for highly regulated industries like aerospace and medical.

INSPECTION/REVERSE

ENGINEERING

Aberlink CMM

A fully programmable 3D CMM capable of measuring to 3um.

It can accommodate components up to 350mm cube, is very quick and easy to program and use, and can produce simple to very detailed inspection report.

It can accommodate components up to 350mm cube, is very quick and easy to program and use, and can produce simple to very detailed inspection report.

Hexagon 7 axis

The all-in-one solution for portable 3D measurement

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications. With usability central to its design, this is an articulating measuring arm that can’t be beaten when it comes to ease of movement and ease of measurement. All this adds up to a far more productive and versatile arm that delivers high-accuracy measurement results more quickly and more easily than ever before.

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications. With usability central to its design, this is an articulating measuring arm that can’t be beaten when it comes to ease of movement and ease of measurement. All this adds up to a far more productive and versatile arm that delivers high-accuracy measurement results more quickly and more easily than ever before.

Keyence VHX700 Microscope

The all-in-one solution for portable 3D measurement

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications. With usability central to its design, this is an articulating measuring arm that can’t be beaten when it comes to ease of movement and ease of measurement. All this adds up to a far more productive and versatile arm that delivers high-accuracy measurement results more quickly and more easily than ever before.

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications. With usability central to its design, this is an articulating measuring arm that can’t be beaten when it comes to ease of movement and ease of measurement. All this adds up to a far more productive and versatile arm that delivers high-accuracy measurement results more quickly and more easily than ever before.

TOOL MANAGEMENT

Haimer Heatshrink

The latest in heat shrink tooling technology, providing

exceptionally accurate tool holding with zero tool runout

achievable, long tool applications and ultra high clamping

forces for the most demanding metal cutting conditions.

Haimer Toolpresetter

The latest in digital tool pre-setting technology,

capable of measuring tooling to 1u. It guarantees

tooling is set exceptionally accurately for the high

precision applications and demanding high metal

removal conditions. With direct DNC link to all

machines, precise and efficient machine setting

is achieved.

ADDITIONAL SERVICES

TIG/MIG Welding Services

High specification TIG and MIG welding equipment

providing the ability to weld most materials.

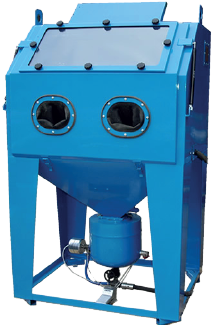

Shot Blasting Facilities

Fully enclosed large capacity shot blasting facility.

Heat Treatment Facilities

A large 1m cube capacity computer controlled furnace.

Case and through hardened capabilities but essentially

used for annealing and stress relieving to ensure

precision machining of complex components.